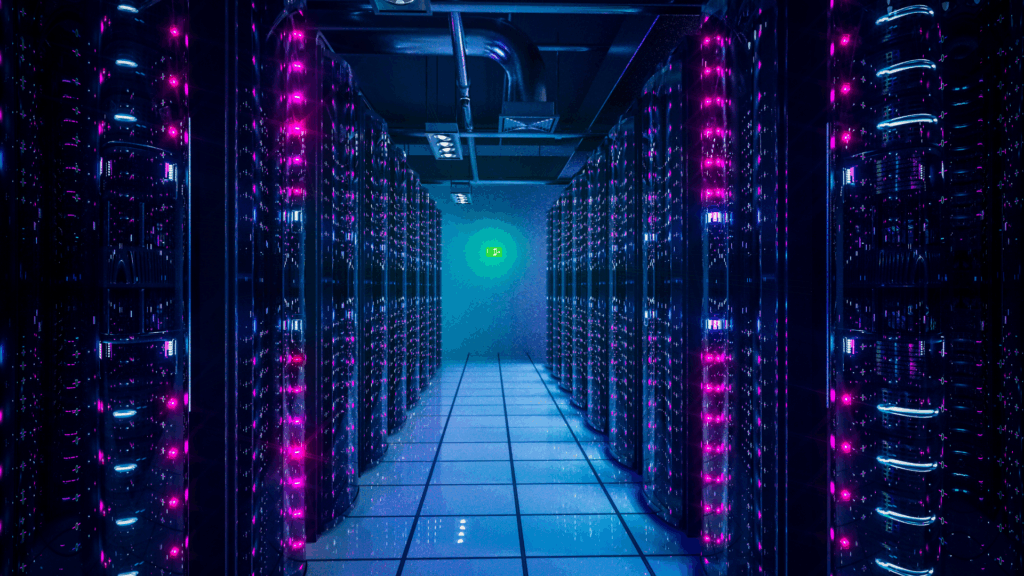

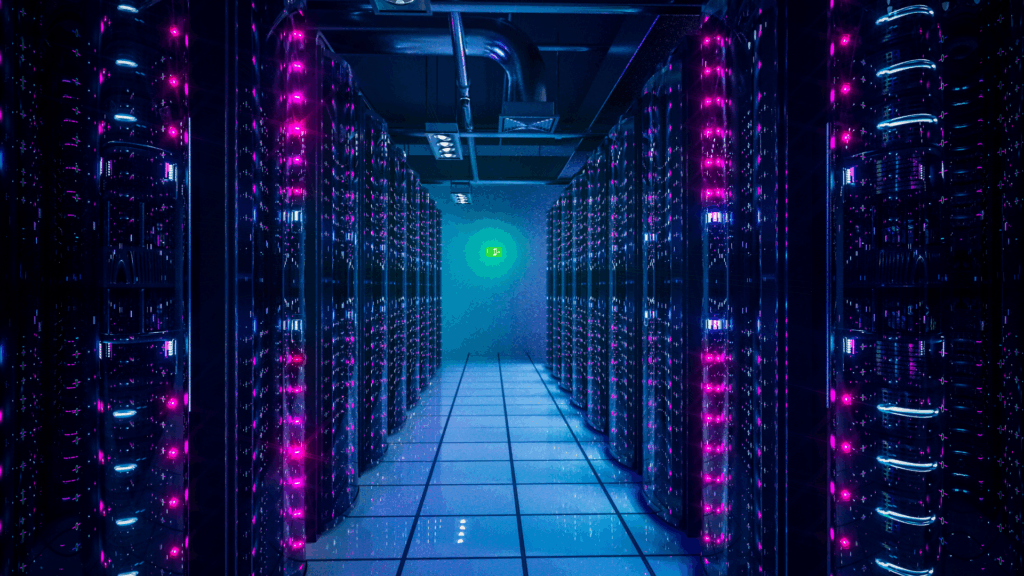

The AI Boom and the New Heat Equation

Artificial intelligence has entered a period of explosive growth. Every day, hyperscale data centers add racks of GPUs and specialized AI chips capable of trillions of calculations per second. These processors consume enormous amounts of power and generate equally enormous heat loads that sometimes exceed 1,000 watts per chip.

Traditional air-cooling and even advanced direct-to-chip liquid systems are reaching their physical limits. Fans, chillers, and HVAC infrastructure must work harder, drawing more energy while struggling to maintain optimal temperatures. The result is a bottleneck that threatens both computational performance and sustainability goals.

According to the International Energy Agency, data centers already account for 1–1.5 % of global electricity use, and that number is climbing rapidly with AI adoption. Maintaining this growth trajectory demands radically more efficient thermal management.

Why Conventional Cooling Can’t Keep Up

Air cooling depends on convective heat transfer, which becomes inefficient as component density increases. Direct-to-chip liquid loops improve heat capture but require complex plumbing and can’t always handle rapid power spikes or tight rack spacing.

As rack densities climb and water-use restrictions tighten, data-center designers are searching for alternatives that deliver:

- Greater thermal efficiency

- Smaller footprints

- Reduced water and refrigerant dependence

- Lower total energy consumption

That’s where immersion cooling and the proper fluid enter the picture.

The Science of Two-Phase Immersion Cooling

Two-phase immersion cooling submerges processors and components in a dielectric liquid that boils on contact with heat. The vapor rises, condenses on a heat-exchanger coil, and returns to liquid form, creating a silent, sealed system that efficiently removes heat with no pumps or chillers required.

This phase-change process offers heat-transfer coefficients that are orders of magnitude higher than those of air cooling, enabling denser, quieter, and more sustainable computing environments.

SF 649™ Engineered Fluid: Built for Performance and Sustainability

Developed by Standard Fluids Corporation, SF 649™ Engineered Fluid is a C6 fluoroketone—a derivative of the same FK-5-1-12 molecule that powers our SF 1230™ Fire Protection Fluid.

It’s engineered for high-performance data centers, AI clusters, and supercomputing environments, delivering:

- Ultra-low GWP (~1)

- Zero ODP

- High dielectric strength

- Excellent material compatibility

- Non-flammable, non-corrosive properties

By pairing exceptional thermal performance with environmental responsibility, SF 649 fluid helps operators meet both efficiency and ESG targets.

Learn more about SF 649 fluids.

Engineering Reliability into Every System

Immersion success depends as much on system design as on chemistry. Standard Fluids partners with tank manufacturers, integrators, and OEMs to ensure reliable performance through:

- Moisture and oxygen control

- Continuous filtration and conditioning

- Optimized condensation and heat-exchange loops

These measures extend fluid life and deliver multi-year reliability, even under the heaviest AI workloads.

Cooling Smarter, Cooling Greener

By replacing water-intensive or refrigerant-based systems, SF 649 fluid enables data centers to reduce both energy use and water consumption, thereby improving PUE (Power Usage Effectiveness) and meeting global sustainability mandates.

The result: higher computing density, lower operational costs, and a smaller environmental footprint—all powered by a fluid designed for the next generation of technology.

Key Takeaway

AI isn’t just transforming computing. It’s transforming infrastructure. As workloads intensify and sustainability goals tighten, two-phase immersion cooling with SF 649 fluid offers a path forward that’s cleaner, quieter, and cooler than ever before.

Explore how SF 649 fluid supports sustainable AI infrastructure