Immersion Cooling - Industrial Applications

SF 649™ Engineered Fluid

SF 649™ Engineered Fluid for Industrial Cooling Applications

With the ever-increasing need for effective heat transfer solutions, SF 649 fluid offers a safe, efficient, and environmentally friendly option. This fluid is ideal for a variety of industrial cooling applications, providing a reliable alternative to traditional solutions.

What is SF 649 fluid?

SF 649 fluid is a versatile heat transfer fluid effective in systems where non-flammability, performance and environmental considerations are important. It is suitable for applications such as computer and data center cooling, electronics cooling, lithium-ion battery cooling and various organic Rankine cycle applications, including diesel engines, generators, geothermal, and solar systems.

Enhancing Industrial Cooling with SF 649 fluid

Utilizing SF 649 fluid for immersion cooling can significantly boost efficiency, reduce costs and minimize dependence on natural resources throughout the complete lifecycle of industrial systems — from initial design and construction to ongoing maintenance and operations. Embrace the future of cooling solutions with the cutting-edge technology offered by Standard Fluids, supported by our extensive scientific expertise.

Immersion Cooling with SF 649 fluid

Immersion cooling involves cooling industrial systems, computers, and data centers by submerging the equipment directly into an electrically non-conductive liquid such as SF 649 fluid. The heat produced by the components is efficiently transferred directly to the fluid, eliminating the need for traditional cooling components like interface materials, heat sinks, fans, shrouds, and sheet metal. This method offers a more streamlined and efficient cooling solution compared to conventional approaches.

Optimizing Strategy, Performance, Cost and Sustainability

Adaptability Across Geographies and Environments: Effortlessly deploy cooling systems with a consistently efficient infrastructure worldwide, irrespective of location decisions.

Efficient Scaling through Streamlined Designs: Achieve enhanced scalability with smaller systems and simplified topologies, eliminating the complexities of airflow management.

Cost-Effective Operations: Address evolving workload requirements while minimizing capital expenditure by reducing or eliminating air-cooling infrastructure. Enhanced cooling efficiency leads to reduced electricity costs associated with ancillary cooling needs.

Lower Power Usage Effectiveness (PUE) and Water Consumption: Achieve impressively low PUEs, enabling the construction of more power-efficient and sustainable systems. Additionally, cut down or eliminate water waste by implementing single-phase or two-phase immersion cooling complemented by the use of dry coolers.

Applications

Enhance cooling efficiency: SF 649 fluid provides superior cooling performance, helping data centers manage the heat generated by high-density servers and other electronic equipment.

Reduce costs: Data centers can reduce their reliance on traditional air-cooling systems by using SF 649 fluid, reducing both capital and operational costs.

Lower PUE: Achieve lower Power Usage Effectiveness (PUE) with immersion cooling, resulting in more energy-efficient data center operations.

Eliminate water waste: Immersion cooling with SF 649 fluid eliminates the need for water in cooling processes, contributing to more sustainable operations.

Support demanding workloads: SF 649 fluid effectively cools high-performance computing systems, supporting new and more compute-intensive workloads.

Increase performance per watt: The superior cooling efficiency of SF 649 fluid allows for higher performance per watt, making supercomputing systems more effective and energy-efficient.

Improve hardware reliability: By maintaining optimal temperatures, SF 649 fluid helps improve the reliability and longevity of high-performance computing hardware.

Reduce latency: Efficient cooling with SF 649 fluid minimizes thermal throttling, reducing latency and enhancing overall system performance.

Implement adaptable cooling systems: SF 649 fluid enables the deployment of adaptable cooling solutions for edge and 5G applications, ensuring consistent performance across various environments.

Roll out high-density edge units: Efficient cooling with SF 649 fluid supports the rollout of high-density edge units, meeting current and future workload demands.

Prolong asset lifespan: The use of SF 649 fluid in sealed immersion-cooled units helps prolong the lifespan of edge and 5G equipment by preventing thermal degradation.

Enhance mining performance: SF 649 fluid provides efficient cooling for cryptocurrency mining operations, improving performance per watt and reducing energy costs.

Reduce operational costs: SF 649 fluid helps reduce the operational costs of mining facilities by eliminating the need for traditional air-cooling infrastructure.

Liquid Cooling Solutions Enabled by Standard Fluids

Standard Fluids’ innovative products support applications in both single-phase and two-phase immersion cooling, as well as direct-to-chip applications.

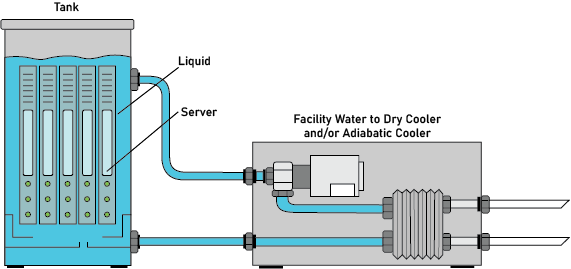

Single-Phase Immersion Cooling: In single-phase immersion cooling, the fluid remains in its liquid phase. Electronic components are directly immersed in a dielectric liquid within a sealed yet easily accessible enclosure. The heat from electronic components transfers to the fluid, and pumps are often employed to circulate the heated fluid to a heat exchanger. There, it undergoes cooling before being recirculated back into the enclosure.

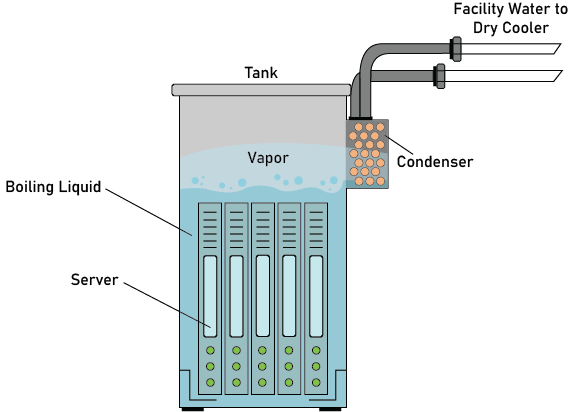

Two-Phase Immersion Cooling: Two-phase immersion cooling involves the boiling and condensation of the fluid, significantly enhancing heat transfer efficiency. Electronic components are immersed in a dielectric liquid within a sealed yet easily accessible enclosure. Heat from the components causes the fluid to boil, generating vapor that rises from the liquid. The vapor then condenses on a heat exchanger (condenser) within the tank, transferring heat to facility water circulating outside the system.

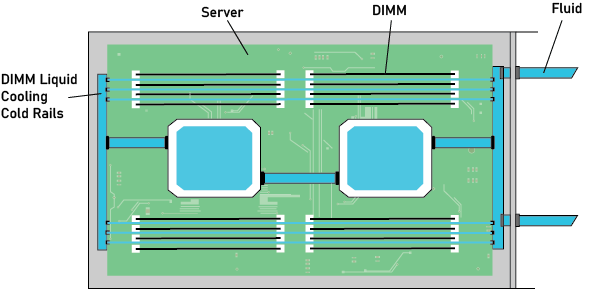

Direct-to-Chip Cooling: Direct-to-chip cooling expels heat by circulating fluid through cold plates attached to electronic components. The fluid never makes direct contact with the electronics.

While non-dielectric fluids (e.g., water, glycol) are common in direct-to-chip cooling, dielectric fluids can be employed in these applications to mitigate leak-related risks, thereby enhancing hardware and IT equipment reliability. Direct-to-chip cooling can be implemented using both single-phase and two-phase technologies.

Technical Specifications

Boiling Point: 49°C

Pour Point: -108°C

Molecular Weight: 316 g/mol

Critical Temperature: 169°C

Critical Pressure: 1.88 MPa

Vapor Pressure: 40 kPa

Heat of Vaporization: 88 kJ/kg

Liquid Density: 1600 kg/m³

Coefficient of Expansion: 0.0018 K⁻¹

Kinematic Viscosity: 0.40 cSt

Absolute Viscosity: 0.64 cP

Specific Heat: 1103 J/kg-K

Thermal Conductivity: 0.059 W/m-K

Surface Tension: 10.8 mN/m

Solubility of Water in Fluid: 20 ppm by wt

Dielectric Strength 0.1″ gap: >40 kV

Dielectric Constant @ 1kHz: 1.8

Volume Resistivity: 10¹² Ohm-cm

Global Warming Potential (GWP): 1

Compatibility and Stability

SF 649 fluid is compatible with a broad spectrum of construction materials, eliminating the need for specialized piping or handling systems. Its stability in storage and high dielectric constant ensure safe, direct contact in most electronics and computing applications.

Environmental Health and Safety

SF 649 fluid has been rigorously evaluated to confirm its minimal environmental impact. With an atmospheric lifetime of just five days, its potential to affect climate change is significantly limited. The photolytic breakdown of SF 649 fluid produces by-products that do not harm the stratospheric ozone layer, affirming its ozone depletion potential of zero.

Resources and Support

Standard Fluids offers global support for SF 649 fluid, with dedicated sales, technical, and customer service resources. Our technical service laboratories in the U.S., Europe, Japan, Latin America, and Southeast Asia are committed to providing ongoing support.

Frequently Asked Questions about Immersion Cooling

Immersion cooling is a technique for cooling industrial systems by submerging equipment directly into a non-conductive liquid such as SF 649 fluid. The heat generated by electronic components is efficiently transferred directly to the fluid, eliminating the need for traditional cooling components like interface materials, heat sinks, fans, shrouds, and sheet metal.

Immersion cooling with Standard Fluids’ products offers increased thermal efficiency, enhanced performance, and improved system reliability. This method eliminates the need for complex airflow management, reducing capital and operating expenses.

In immersion cooling, IT hardware is directly submerged in a sealed enclosure filled with dielectric liquid. Direct-to-chip cooling circulates fluid through cold plates on electronic components, keeping the fluid separate from the electronics.

Considerations include tank design, fluid containment, material compatibility, and fluid hygiene for single-phase immersion cooling. Two-phase immersion cooling offers greater heat transfer efficiency and typically requires less complex cooling infrastructure.