Immersion Cooling - Industrial Applications

SF 7200™ Engineered Fluid

Standard Fluids 7200™ Engineered Fluid for Industrial Applications

SF 7200 fluid is meticulously designed to meet the rigorous demands of various industrial applications, including semiconductor manufacturing, data center cooling, and precision cleaning. This advanced hydrofluoroether (HFE) fluid delivers exceptional performance while ensuring environmental sustainability and worker safety.

What is SF 7200 Fluid?

SF 7200 fluid is a versatile, high-performance hydrofluoroether (HFE) fluid. Known for its non-flammability, low toxicity, low global warming potential (GWP), and zero ozone depletion potential (ODP), this fluid excels in applications requiring superior thermal management and electrical insulation.

Unique properties include:

- Boiling Point: 76°C

- Molecular Weight: 264 g/mol

- Critical Temperature and Pressure: 210°C and 2.01 MPa

- Dielectric Constant: 7.3

Unique application profile includes:

- Semiconductor manufacturing

- Data center cooling

- Precision cleaning

- Specialty solvents

- Heat transfer applications

Optimizing Industrial Processes with SF 7200 Fluid

Implementing SF 7200 fluid in industrial processes enhances efficiency, reduces operational costs, and minimizes environmental impact. This fluid supports various applications from initial design and construction to ongoing maintenance.

Advanced Immersion Cooling with SF 7200 Fluid

Immersion cooling with SF 7200 fluid involves submerging electronic components in a non-conductive liquid, allowing for direct and efficient heat transfer. This method eliminates the need for traditional cooling components, providing a streamlined and effective alternative to conventional cooling methods.

Liquid Cooling Solutions Enabled by Standard Fluids

Standard Fluids’ innovative solutions support both single-phase and two-phase immersion cooling, as well as direct-to-chip applications.

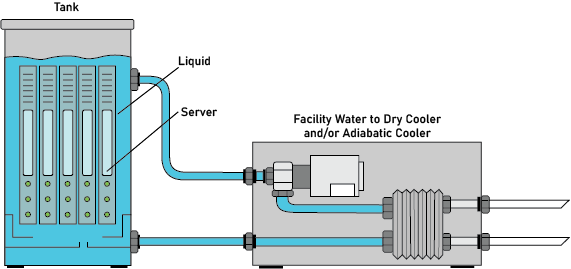

Single-Phase Immersion Cooling: Submerge electronic components in a dielectric liquid, where the fluid remains in its liquid phase. Heat transfer occurs directly from the components to the fluid, which is then circulated to a heat exchanger for cooling.

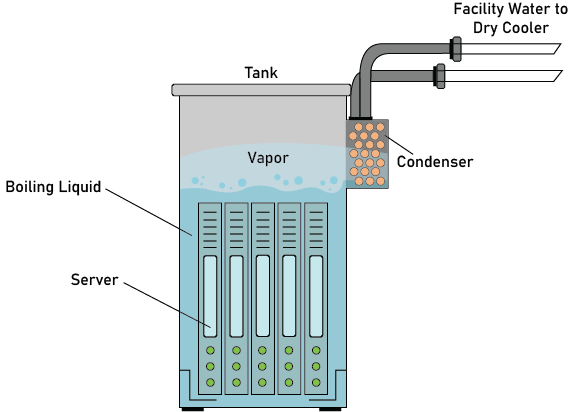

Two-Phase Immersion Cooling: Utilizes the boiling and condensation of the fluid to enhance heat transfer efficiency. Electronic components are immersed in a dielectric liquid, where the heat causes the fluid to boil and vaporize. The vapor condenses on a heat exchanger, transferring heat to facility water.

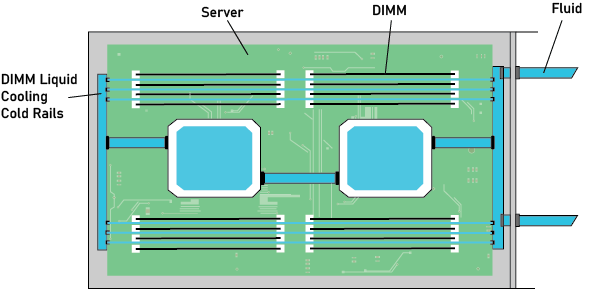

Direct-to-Chip Cooling: Circulate fluid through cold plates attached to electronic components, without direct contact with the electronics. This method can employ both dielectric and non-dielectric fluids.

Features and Benefits of SF 7200 Fluid

Effective Cleaning and Rinsing

Key Benefits: Ideal for light-duty cleaning and rinsing of:

- Particulates

- Fluoro lubes

- Light oils

- Fluoro greases

Technical Specifications

Key Benefits: Non-volatile residue (NVR) < 1.0 ppm

Solubility of water in fluid: 92 ppm by weight

Environmental Safety

Key Benefits: Low GWP and zero ODP ensure minimal environmental impact.

Technical Specifications: Global Warming Potential (GWP): 34; Ozone Depletion Potential (ODP): Zero

Non-Flammable and Non-Conductive

Key Benefits: Provides safe usage in various applications without the risk of ignition or conductivity.

Technical Specifications: Flash Point: None; Electrical Conductivity: Non-Conductive.

High Performance in Heat Transfer

Key Benefits: Exceptional dielectric heat transfer properties make it suitable for cooling applications in data centers and semiconductor manufacturing.

Technical Specifications: Boiling Point: 76°C; Heat of Vaporization: 119 kJ/kg.

Compatibility

Key Benefits: Works as a direct drop-in replacement for 3M™ Novec™ 7200, ensuring seamless transition without the need for system modifications.

Technical Specifications: Kinematic Viscosity: 0.41 cSt; Surface Tension: 13.6 mN/m.

Applications of SF 7200 Fluid

High-Performance Heat Transfer for Modern Infrastructure

SF 7200 provides stable, efficient cooling for high-density data center hardware and advanced electronics. Its low viscosity and excellent thermal properties support reliable operation in demanding environments.

Technical Specification: Pour Point: –138°C

Reliable, Non-Conductive Cooling for Immersed Systems

Ideal for single-phase immersion cooling applications, SF 7200 delivers fast heat removal, chemical stability, and exceptional dielectric strength—protecting sensitive components while maintaining thermal efficiency.

Technical Specification: Dielectric Strength (0.1″ gap): > 25 kV

Efficient Thermal Management for Precision Systems

With strong thermophysical properties and excellent material compatibility, SF 7200 supports consistent heat transfer across semiconductor tools, power electronics, and precision industrial systems.

Technical Specification: Specific Heat: 1220 J/kg·K

Engineered for Delicate, High-Value Semiconductor Processes

SF 7200 ensures stable thermal management during wafer handling, lithography, and etch processes. Its low toxicity profile and high purity make it ideal for applications where cleanliness and performance matter most.

Technical Specification: Liquid Density: 1.42 g/mL

Highly Effective Solvent for Precision Cleaning and Rinsing

SF 7200 is a versatile cleaning agent with excellent solvency and fast drying time, making it ideal for vapor degreasing, rinsing, and removing particulate and light organic residues from sensitive components.

Technical Specification: Molecular Weight: 264 g/mol

Gentle, Non-Damaging Cleaner for Archival Film and Specialty Media

Safe for delicate substrates, SF 7200 evaporates cleanly and leaves no residue—making it suitable for cleaning and restoring motion picture film, archival media, and other sensitive materials.

Technical Specification: Dielectric Strength: *> 25 kV

Isomeric Comparison of SF 7200 fluid vs. 3M™ Novec™ 7200

SF 7200 fluid:

Formulation: Ethoxy-nonafluorobutane (C₄F₉OC₂H₅)

Boiling Point: 76°C

Density: 1.42 g/ml

Surface Tension: 13.6 dynes/cm.

3M™ Novec™ 7200:

Formulation: Ethoxy-nonafluorobutane (C₄F₉OC₂H₅)

Boiling Point: 76°C

Density: 1.42 g/ml

Surface Tension: 13.6 dynes/cm.

Physical Properties of SF 7200 fluid

Boiling Point: 76°C

Density: 1.42 g/ml

Viscosity: 0.61 cSt

Surface Tension: 13.6 dynes/cm

Global Warming Potential (GWP): 34

Ozone Depletion Potential (ODP): Zero

Flash Point: None (Non-Flammable)

Electrical Conductivity: Non-Conductive

Heat of Vaporization: 119 kJ/kg

Specific Heat: 1220 J/kg·K

Kinematic Viscosity: 0.41 cSt

Dielectric Strength Range (0.1″ gap): > 25 kV

Compatibility and Stability of SF 7200 Fluid

SF 7200 fluid is compatible with a broad spectrum of construction materials, eliminating the need for specialized piping or handling systems. Its stability in storage and high dielectric constant ensure safe direct contact in most electronics and computing applications.

Environmental Health and Safety

SF 7200 fluid has been rigorously evaluated to confirm its minimal environmental impact. With an atmospheric lifetime of less than one year, its potential to affect climate change is significantly limited by its very low GWP. The photolytic breakdown of SF 7200 fluid produces by-products that do not harm the stratospheric ozone layer, affirming its ozone depletion potential of zero.

Resources and Support for SF 7200 fluid

Standard Fluids offers global support for SF 7200 fluid with dedicated sales, technical, and customer service resources. Our technical service laboratories in the U.S., Europe, Japan, Latin America, and Southeast Asia are committed to providing ongoing support.

Frequently Asked Questions about SF 7200 fluid

SF 7200 fluid is a high-performance hydrofluoroether (HFE) fluid designed for various industrial applications, offering non-flammability, low toxicity, and minimal environmental impact.

SF 7200 fluid provides efficient heat transfer, reduces operational costs, and enhances system reliability. It is particularly suitable for semiconductor manufacturing and data center cooling.

Immersion cooling involves submerging electronic components in SF 7200 fluid, allowing direct and efficient heat transfer. This method eliminates the need for traditional cooling components, providing a streamlined and effective alternative.

SF 7200 fluid is non-flammable and low in toxicity, making it safe for various applications. It also has a minimal environmental impact, with a very low GWP and zero ODP.